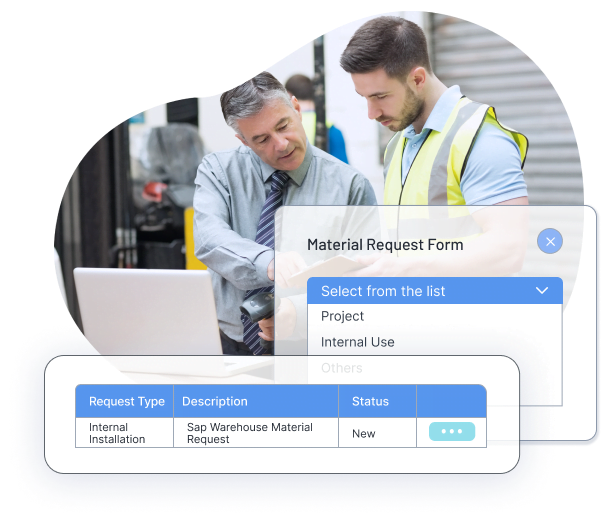

Track All Warehouse Movements Instantly

Warehouse-Material Management in Facility Management Activities is a process that involves the effective management of materials, consumables and inventories in the storage areas of the teams providing services. This process starts from material receiving and includes storage, tracking, distribution and inventory control. The main goal is to optimize material flow, control stock levels and manage warehouse operations efficiently. By working in integration with the procurement process, support is provided for the timely procurement and use of the necessary materials.

Inventory Management: It covers activities such as managing inventories effectively, inventory tracking, shipment planning and monitoring inventory turnover.

Product Placement: The right product placement strategy is critical for effective utilization of warehouse space and increasing inventory turnover.

Shipment Management: Regular and efficient management of shipments ensures customer satisfaction and accurate shipment of products.

Cost Savings: Proper inventory management, efficient use of warehouse space and accurate shipment management reduce operational costs.

Customer Satisfaction: Accurate product stock and shipment management in a well-managed warehouse increases employee/customer confidence in the business.

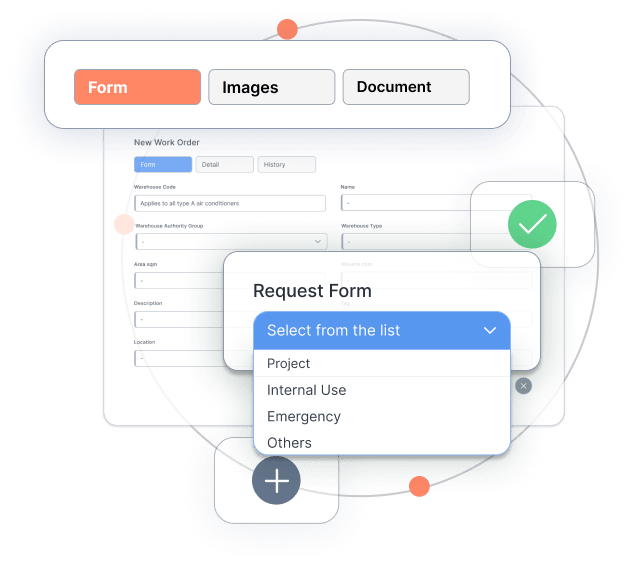

Efficient Digital Warehouse - Materials Management